As I progress in my build I find

myself dreading the weekend. I have completed my second week of electric guitar

construction which meets two days a week. Sometimes it’s absolutely nerve racking

knowing that I could slip up and make a mistake at any given moment. However, the

feeling of making something absolutely perfect in shape and size in the work piece

is next to none in the luthierie world focus is absolutely key in producing a

well built and aesthetically pleasing guitar.

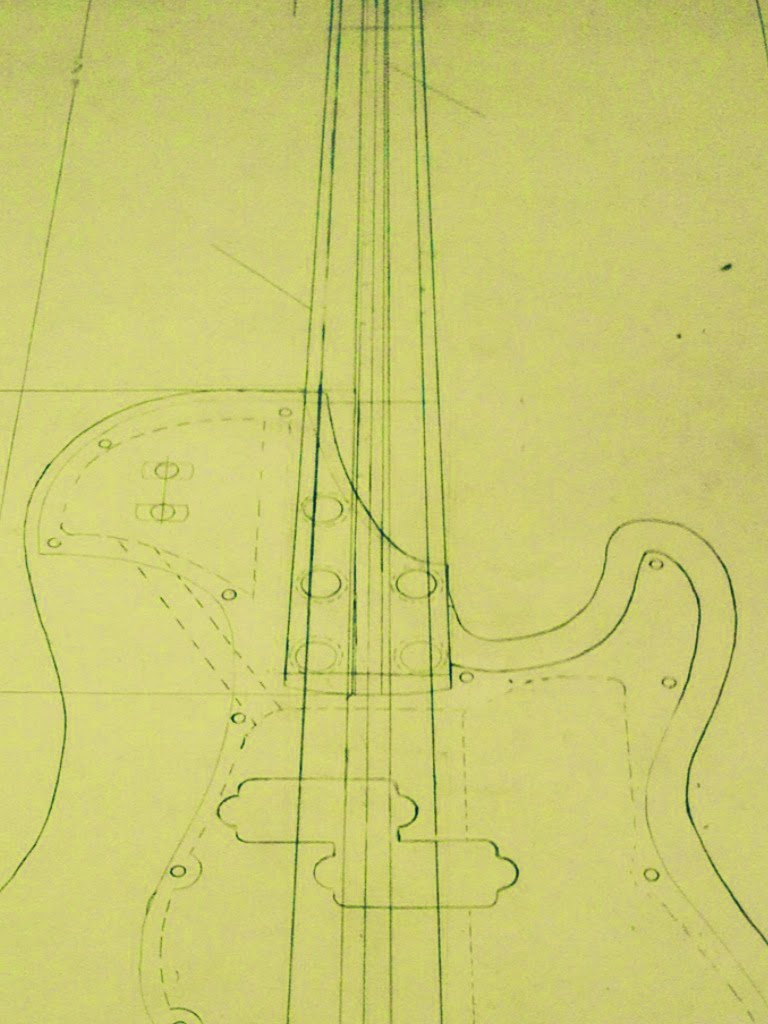

This week we began with a demonstration on using routers. For electric guitar construction routers are the most frequently used tool. Last week I used the router table to flush trim the body by running the bearing of the bit over my template. This week I started to route a channel out to connect my two control cavities. To do this I drilled a hole with a Forstner bit on either side of the channel and then set up a straight edge to run the base of the router along.

I did this before gluing on my cap because the channel would run out past where I wanted my pick guard to be. Once the channel was routed and cleaned up with a bit of sandpaper I lined up the flamed cherry drop cap buy drilling holes and filling them with dowels to prevent the wood from shifting when being glued. To glue the cap on I used a veneer press with 2 pieces of flat plywood on either side to distribute clamping pressure evenly. After doing a dry run I taped off the cavity and spread some glue around evenly and pressed the boards together waiting 90 minutes before unclamping.

In the mean time I began construction of the neck and fingerboard. I ran into a hiccup with my fingerboard. I set up the fretslot table and cut my 21 frets using a 35 inch template.

On Fender style fingerboard the nut shelf is built into the

fingerboard; therefore when making a Fender style fingerboard you do not want

to cut off the fingerboard at the nut….. I did, so I had to do some creative

thinking and use some excess fingerboard to give the illusion of this shelf

that wasn’t cut off. First I cut the excess so that the grain lines matched up

as much as possible then I squared up the board with a hand plane and disc

sander. After that I removed the safety guard from the table saw to create a

miter on the edge of the board. I'll glue this little chunk onto the board after

I glue on my fingerboard.

The next step was for me to route

out a channel for my truss rod. The first thing I did was take my flame maple

board and square it up and then plane it down to the proper thickness (that

being just over ¾ of an inch). Afterwards I routed out a channel for my truss

rod.

After cleaning up the channel with some sand paper I routed out two

additional channels for some carbon fiber reinforcement beams.

I then created

some plugs for the end of the boards. This ensures that there isn’t any

movement of the carbon fiber boards and keeps gunk out of the truss rod channel

as well as creating a more professional appearance. I then unclamped the body to make sure everything was glued properly and everything looks good!

Tune in next week for the next addition to the build: more on the neck construction process

-John Potts